Low-volume, high-mix manufacturing requires equipment that can switch between parts quickly while maintaining stable accuracy. In this context, many buyers evaluate 5 axis machining center manufacturers based on adaptability, configuration options, and long-term operating reliability. A five-axis platform reduces repeated clamping and setup changes, which is critical when part designs vary frequently. This flexibility allows factories and EPC partners to handle diverse component geometries without sacrificing workflow continuity or process consistency.

Reduced Setup Time and Process Integration

One key reason these machines suit mixed production is their ability to complete complex surfaces in a single setup. This is where 5 axis high speed machining becomes practical for small batches, because faster spindle response and coordinated axis movement shorten cycle times without pushing aggressive cutting parameters. For procurement teams and industrial distributors, fewer setups also mean lower tooling risk and more predictable scheduling. They can integrate new orders into existing lines with less disruption to manpower planning and fixture preparation.

Equipment Configuration Supporting Mixed Orders

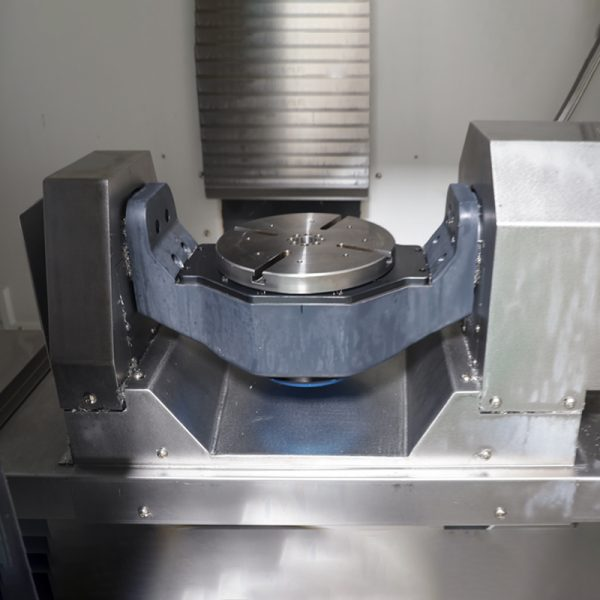

A representative example is the Leichman LK-U220T Five-Axis Machining Center, configured for flexible shop environments. Leichman positions this model with a 600 × 400 × 330 mm XYZ travel range, combined with a ±110° A-axis and full 360° C-axis rotation. The 20000 rpm BT30 spindle with 5.5 kW power supports varied materials and surface requirements, while a 21-tool clamp-arm magazine with a 4-second tool change helps manage frequent process changes. Positioning accuracy of ±0.008 mm supports repeatability across short runs without excessive recalibration.

Practical Value for B2B Manufacturing Chains

For international traders, machine agents, and metal processing factories, five-axis machining center manufacturers provide solutions that enable responsive order handling and reduced inventory pressure. These 5 axis high speed machining centers support customization without excessive lead times, aligning with service models that emphasize fast technical response and coordinated delivery. These characteristics explain why 5 axis machining center manufacturers and their 5 axis high speed machining solutions are well suited to low-volume, high-mix production environments where adaptability matters more than sheer output scale.