Beyond efficiency gains, robust warehouse logistics and integrated internal logistics serve as critical safeguards against operational fragility in manufacturing. Inconsistent processes introduce points of failure – from data blind spots to labor bottlenecks – that escalate costs and disrupt throughput. A resilience-focused approach addresses these vulnerabilities systematically.

Securing Data Integrity as an Operational Imperative

Material diversity and complex workflows amplify risks from manual tracking: duplicate entries, inconsistent records, and inaccurate inventory visibility. These aren’t mere inefficiencies; they represent systemic vulnerabilities in warehouse logistics. PassionIOT’s “Smart Access” mitigates this risk layer by implementing automated, high-precision inventory control. By eliminating manual data variance and providing real-time component traceability, it establishes a single source of truth. This foundational accuracy is non-negotiable for reliable internal logistics planning and execution, directly reducing stoppages from material unavailability.

Reducing Labor Dependency in Material Movement

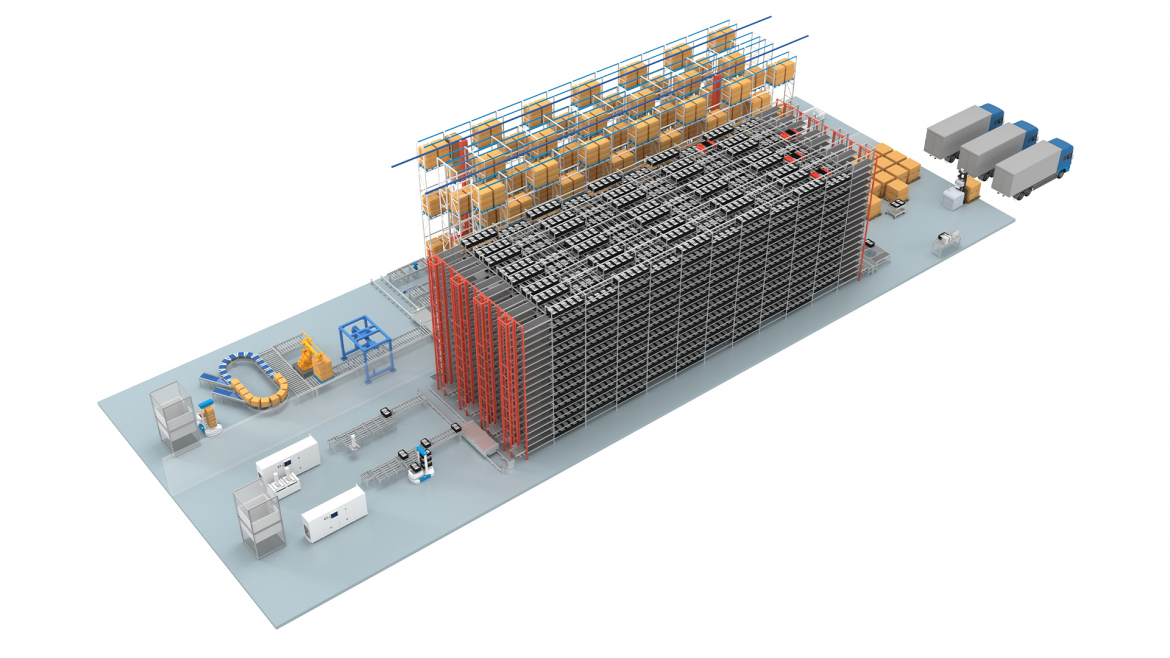

Reliance on manual material handling creates inherent operational fragility – delays from labor shortages, inconsistent distribution timing, and physical search waste. These internal logistics constraints become critical single points of failure. PassionIOT’s “Directed Logistics” counters this through autonomous material transport via AGVs. This unmanned system ensures a predictable, continuous flow from storage to point-of-use, independent of workforce variables. It transforms warehouse logistics from a potential bottleneck into a resilient, just-in-time conduit, significantly lowering exposure to labor-related disruptions and physical workflow congestion.

Conclusion

Reconceiving material flow through the lens of operational risk reveals that precision warehouse logistics and resilient internal logistics function as vital shock absorbers. By embedding automated accuracy and autonomous mobility, manufacturers convert potential friction points – data opacity, labor variance, physical bottlenecks – into inertial momentum. This transforms the material ecosystem from a passive repository into an active, stabilizing force, allowing production to proceed not merely faster, but with assured continuity against unforeseen pressures. The outcome is an intrinsically fortified operational backbone.